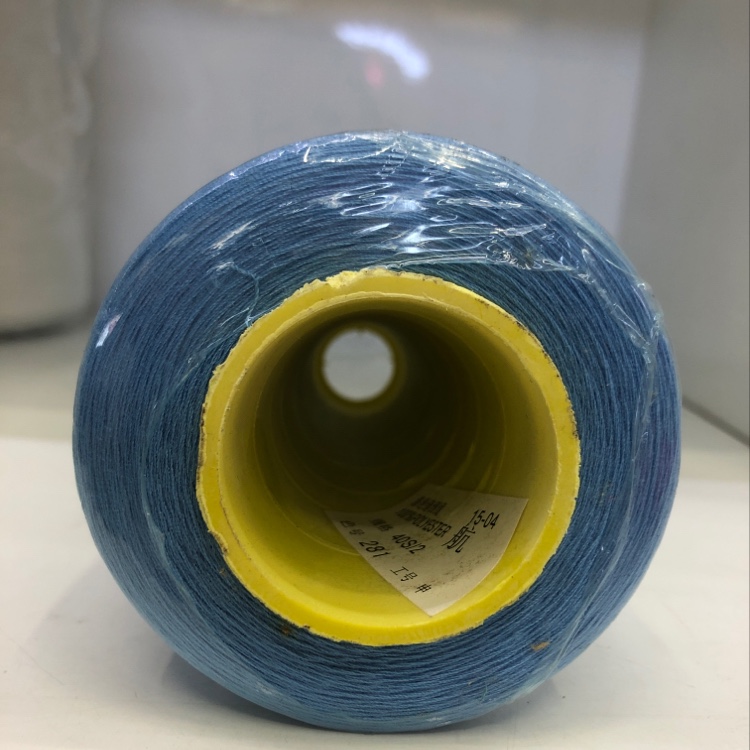

Starting from the details: the secrets and advantages behind the 40/2 specification

In the textile industry, every thread has a unique story. Today we are going to introduce 40/2 this classic specifications of the light blue wire. What kind of mystery is hidden behind the numbers? In fact, "40" means that the yarn is of moderate thickness, and the fabric is soft and not easy to break; "2" means that two single strands are twisted into one, which makes the overall strength higher and the wear resistance stronger. This combination can not only meet the needs of daily sewing, but also cope with complex process challenges.

The Beauty of light blue: An Analysis of the Impact of Color on the Value of Textiles

Color is often the first thing people notice. This wire uses the classic light blue (281), which can not only integrate into a variety of fabric color schemes, but also show a low-key and elegant unique temperament in specific occasions. Especially in the production of professional or business clothing, this fresh blue has become an indispensable existence. Not only that, light blue also has good covering performance and dyeing and finishing compatibility, providing designers with more possibilities.

8000y model interpretation: why it has become a benchmark material in the industry

In addition to specifications, we also need to pay attention to specific model information. "8000y" means that the product has an ultra-high production standard supported by an excellent quality control system. Its emergence has redefined the concept of traditional textile accessories and set a new quality benchmark. Every link has been strictly screened and tested, only to bring you the most reliable solution.

The power of stability: how wire quality determines the success or failure of the finished product

For any product that requires precision sewing, the quality of the wire has a direct impact on the final result. If you choose inferior raw materials, it may cause problems such as broken wires or even cracked fabrics. However, this light blue wire is known for its excellent toughness and consistency, even in high-strength continuous operation environment can maintain excellent performance. No matter what type of machining task you are engaged in, you can safely rely on it to complete every step of the operation.

From clothing to crafts: a wide range of applications for light blue wire

Don't think that such a small line can only be limited to ordinary clothing manufacturing! In fact, with the increasingly diversified development of market demand, more and more fields begin to try to apply it. For example, the exquisite embroidery patterns on high-end custom dresses cannot be separated from the help of such professional auxiliary tools. At the same time, it can also be seen that they are active in the creation of handicrafts-weaving tapestries or crochet scarves can add a different charm by adding a few strands of elegant blue.

Enhancing Competitiveness: How to Win Market Favor with High Quality Accessories

In this competitive business environment, a single element is no longer enough to stand out. When everyone is pursuing the ultimate perfection, the selection of top-level supporting parts has become the key. Just imagine, if your factory can take the lead in introducing such high-quality light blue wire resources and form differentiated highlights among peers, will it be easier to attract customers' attention and establish long-term cooperative relations?